Advantages of Dry Decontamination in Extremely Cold Temperatures

In extreme cold, traditional wet decontamination methods pose significant challenges, including hypothermia risks and logistical difficulties with freezing water. Dry Decontamination in extremely cold temperatures presents a critical solution, ensuring effective contaminant removal without water, allowing for safer and more efficient hazmat response in harsh environments.

The Challenges of Cold Weather Decontamination

Cold temperatures can significantly increase the likelihood of hazardous chemical incidents. According to Hazmat Nation and the U.S. Chemical Safety Board (CSB), chemical releases rise in the winter due to the contraction of pipes and materials, increased reliance on heating systems, and potential system failures. These conditions make it essential to have decontamination methods that function effectively in low temperatures to decrease direct health hazard.

Dry Vs. Wet Decontamination: Understanding the Difference

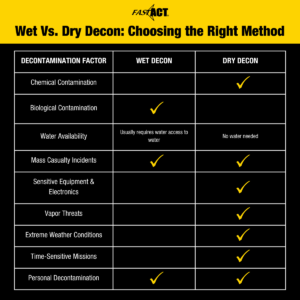

When responding to hazardous material exposure, decontamination is crucial for safety and effectiveness. Wet decontamination—using water, soap, or specialized chemical solutions—has been the standard in hazmat, military, and first responder scenarios. It effectively removes contaminants but requires significant logistical support, including water availability, drainage management, and proper waste disposal.

Dry decontamination, on the other hand, uses absorbent materials, powders, or reactive compounds to neutralize hazards without water. This method reduces setup time, minimizes runoff concerns, and can be more efficient for certain threats, such as chemical and particulate contamination.

Key Benefits of Dry Decontamination in Extremely Cold Temperatures

1. Reduced Risk of Hypothermia

Traditional wet decontamination requires individuals to be exposed to water, which can quickly lower body temperatures, increasing the risk of hypothermia. Dry decontamination methods, such as absorbent powders or wipes eliminate the need for water, allowing for safe decontamination without exposing individuals to the cold.

2. Adaptability to Harsh Environments

Cold weather can make access to decontamination sites difficult due to snow and ice. Dry decontamination solutions do not require large quantities of water, making them more mobile and adaptable to remote or challenging locations where water-based decontamination stations may not be feasible.

3. Effective Contaminant Neutralization

In freezing conditions where water-based decontaminants may become ineffective, dry solutions ensure reliable performance, allowing responders to maintain operational effectiveness.

4. Faster Deployment Time

When responding to a hazardous materials incident, time is critical. Traditional wet decontamination setups require extensive preparation, including securing a water source, setting up containment areas, and ensuring proper drainage. Dry decontamination eliminates these steps, allowing responders to deploy rapidly and reduce contamination exposure time.

5. Enhanced Safety for Personnel and Equipment

Cold weather conditions can make it difficult for responders to operate traditional decontamination equipment. Water-based systems may freeze inside hoses or nozzles, making the equipment unusable. Additionally, responders wearing multiple layers of protective clothing may struggle with wet decontamination, which can lead to ice formation on gear and increased mobility issues. Dry decontamination eliminates these concerns, ensuring both personnel and equipment remain functional in harsh environments.

The Science Behind FAST-ACT Dry Decontamination Process

FAST-ACT is the only dry decontamination works by using materials that decontaminate, contain, and neutralize hazardous substances. FAST-ACT relies on advanced chemistry that breaks down toxic compounds on contact. Unlike commercially available versions of titanium dioxide and magnesium oxide, these materials are manufactured using unique processes that allow for greatly enhanced physical and chemical properties of the components allowing for broad chemical efficacy.

FAST-ACT: A Cold-Weather Method of Decontamination

FAST-ACT Powder is a highly effective decontamination solution, specially designed for use in cold-weather conditions. It rapidly neutralizes harmful chemical agents and hazardous vapors, ensuring safety in environments where other methods may struggle to perform. This powder-based solution, such as the FAST-ACT Decontamination Mitt, is ideal for situations where temperatures drop, as it remains stable and active even in extreme cold, making it a reliable tool for first responders, law enforcement, and military personnel.

Operational Advantages of FAST-ACT in Cold Weather:

- Rapid Neutralization: FAST-ACT quickly adsorbs and neutralizes chemical threats, reducing exposure risks.

- No Water Required: Eliminates the need for liquid decontamination, preventing issues related to freezing or runoff contamination.

- Lightweight and Portable: FAST-ACT Products are designed to ensure ease of transport and rapid deployment in emergencies.

- Environmentally Safe: Unlike water-based decontamination, FAST-ACT reduces environmental impact without the risk of chemical-run off contaminating ecosystems.

Real-World Implications

Cold weather conditions can delay emergency response efforts due to frozen infrastructure, reduced mobility, and the increased difficulty of setting up traditional decontamination stations. Hazardous material spills or leaks in winter require specialized solutions that can be deployed quickly without the need for extensive setup or water sources. The necessity for alternative method of decontamination is particularly crucial in remote locations or regions that experience extreme winter conditions.

Best Practices for Implementing Dry Decontamination in Cold Environments

To maximize the effectiveness of dry decontamination solutions in cold weather, response teams should consider the following best practices:

- Training and Preparedness: Ensure personnel receive hands-on training in applying dry decontamination products and fully understand their capabilities and limitations.

- Storage and Accessibility: Keep dry decontamination supplies in easily accessible locations, especially in areas prone to extreme winter conditions.

- Routine Equipment Checks: Regularly inspect and test decontamination equipment to confirm its functionality in cold weather conditions.

- Integration into Response Protocols: Incorporate dry decontamination methods into standard operating procedures to ensure seamless implementation during emergencies.

Expanding Dry Decontamination Practices in Cold Environments

As the demand for effective decontamination methods grows, more emergency response teams are exploring dry decontamination as an alternative to traditional approaches. Hazmat teams operating in cold regions have noted the necessity of having decontamination solutions that are reliable in freezing conditions. Countries like Canada, Sweden, and Norway have been slowly incorporating dry decontamination alternatives into their existing protocols, recognizing the benefits of these solutions in extreme temperatures.

Future Trends in Cold-Weather Hazmat Response

Innovations in dry decontamination technology continue to improve response capabilities. Some emerging trends include:

- Portable Decontamination Systems: Compact, self-contained decontamination kits that allow first responders to perform dry decontamination quickly in the field.

- Integration with PPE: Future personal protective equipment (PPE) may incorporate built-in dry decontamination solutions, reducing the need for additional equipment.

Conclusion

Overall, Dry Decontamination is a critical advancement in hazmat response, especially in extreme cold conditions where traditional methods may fail. As cold-weather chemical releases continue to pose significant risks, the need for adaptable decontamination solutions, like FAST-ACT, has never been greater. With faster deployment times, enhanced responder safety, and reliable neutralization of contaminants, FAST-ACT stands as the superior choice for hazardous material response in freezing conditions.

Equip your team for cold-weather decontamination. Contact us or visit our training page to learn more about effective solutions for extreme environments.

About Timilon Corporation:

Timilon Corporation is the manufacturer of FAST-ACT®, a proprietary formulation of non-toxic high-performance specialty materials effective at neutralizing a wide range of toxic chemicals with the added capability to destroy chemical warfare agents. The FAST-ACT technology is utilized by leading defense agencies, chemical industrial companies, first responders and HAZMAT teams to quickly and safely eliminate chemical hazards. For more information, reach out to Leticia Menzzano, Marketing Manager, lmenzzano@timilon.com.

FAQs

Why is decontamination more difficult in extreme cold environments?

In freezing and subzero conditions, traditional wet decontamination methods can fail due to frozen water, reduced equipment functionality, and increased hypothermia risk.

What is the difference between dry and wet decontamination in cold weather?

Wet decontamination relies on water and liquid solutions, which can freeze and require extensive setup. Dry decontamination uses absorbent or reactive materials to neutralize contaminants without water, allowing faster deployment and reliable performance in freezing conditions.

Is FAST-ACT effective in subzero temperatures?

Yes. FAST-ACT has been tested and proven to remain effective in extreme cold conditions, including subzero environments, because it does not rely on water or liquid activation.

What operational advantages does FAST-ACT provide in cold weather response?

FAST-ACT enables rapid deployment, eliminates water and runoff concerns, remains lightweight and portable, and ensures continued chemical neutralization when traditional systems freeze or fail.