Applications

DECON

(DEcontamination, COntainment, Neutralization)

FAST-ACT Decontamination Mitts and Wipes provide Individual Protection with small portable decon mitts and wipes for immediate DECON of personal gear, articles, and even skin. The FAST-ACT Decontamination Mitt and the Wipes are a Class I medical device for dual use on surface and skin. The small devices are easy to use by a layperson with minimal training. The compact form is ideal for transportation, storage, and on the go at the warfighter or responder level. The Decontamination Wipes can be used for chemical and radioactive decontamination (removal of radioactive particles).

FAST & FORWARD

Decontamination needs to take place as early as possible, even at or close to the incident site. Our products allow you to perform decontamination fast and forward!

FAST-ACT Products and Kit can be used quickly at the site of contamination or release to quickly adsorb and contain high levels of contamination. Most products are designed for standard contamination densities or just containment, but having a quickly deployable sorbent that offers chemical breakdown at high contamination densities is valuable in the moments right after an incident.

*Skin applications are limited to areas where it is a CE class 1 medical device or covered under TGA approval.

View All Products

Confined Space Operational Vapor Decontamination with pressurized cylinders that dispense FAST-ACT powder into the air to capture and breakdown the airborne chemical hazard. Easily deployed and simple to use much like a fire extinguisher. The FAST-ACT pressurized cylinder can quickly knock down vapors in areas where ventilation may be difficult or impractical.

VAPOR

Waterless Personnel Decontamination

The FAST-ACT Pressurized Cylinders provide a waterless solution for rapid personnel decontamination in the event of chemical exposure. Designed to adsorb and neutralize toxic vapors or liquids on protective gear, it ensures immediate action in field environments where water may be scarce or unavailable. Its lightweight design and controlled discharge make it easy to deploy, giving first responders and military personnel a reliable tool to quickly mitigate chemical threats and prevent harm in critical situations.

Enclosed Space Vapor Neutralization

When toxic chemical vapors accumulate in confined spaces, they can pose significant health risks to anyone nearby. The FAST-ACT Cylinders are ideal for enclosed space vapor neutralization, allowing first responders to neutralize hazardous vapors safely and swiftly. Whether in a building, vehicle, or small, enclosed area, the cylinder’s fast-acting formulation and easy-to-use design provide an efficient, portable solution to protect personnel and civilians from harmful inhalation.

Confined Space Operational Vapor Decontamination with pressurized cylinders that dispense FAST-ACT powder into the air to capture and breakdown the airborne chemical hazard. Easily deployed and simple to use much like a fire extinguisher. The FAST-ACT pressurized cylinder can quickly knock down vapors in areas where ventilation may be difficult or impractical.

Emergency Decontamination for High Contaminated Areas

In the event of a chemical spill, the FAST-ACT Cylinders enable first responders to contain and neutralize toxic liquids on surfaces quickly and effectively. Its rapid deployment reduces the spread of hazardous substances, protecting both personnel and the environment from further contamination. With no formal maintenance required, the cylinders remain a dependable tool for managing chemical spills in emergency situations.

Critical Infrastructure Protection (Event Venues)

Public spaces such as event venues, stadiums, and government buildings are vulnerable to chemical threats, whether from accidental spills or deliberate attacks. The FAST-ACT Cylinders offer a critical line of defense by enabling security and response teams to quickly neutralize chemical vapors or liquids, protecting attendees and staff from exposure. Its portability and ease of use make it an essential tool for safeguarding high-traffic areas in critical infrastructure.

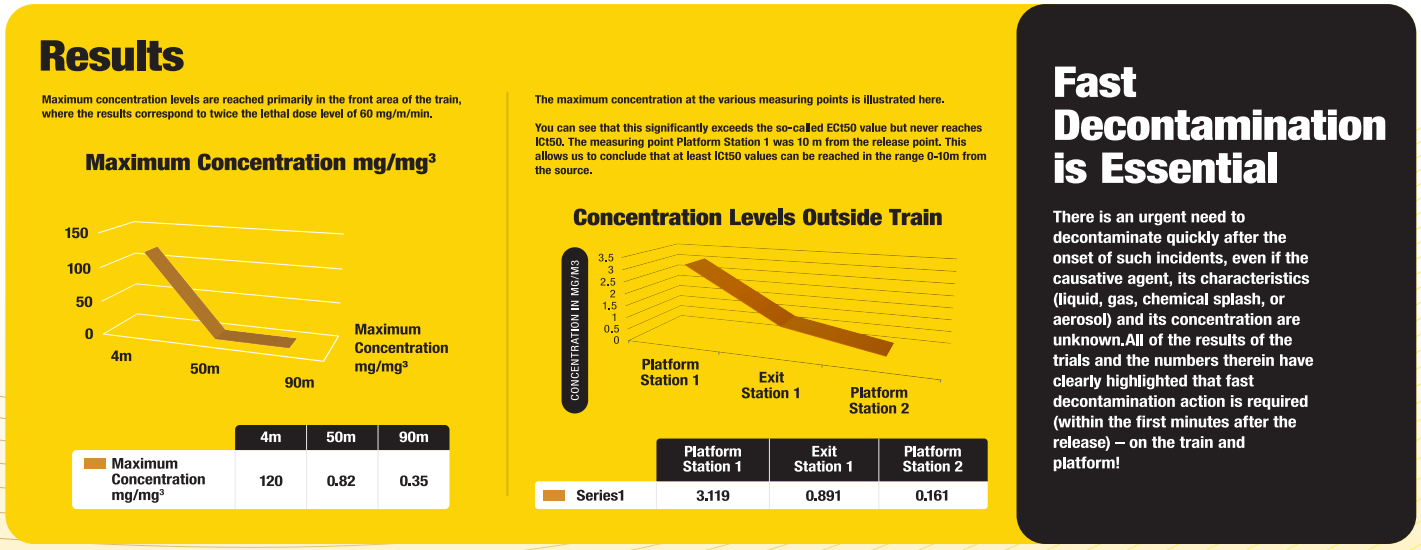

Transportation Safety (Subways, Airports)

Subways, airports, and other transportation hubs are potential targets for chemical incidents. The FAST-ACT Cylinders provide a rapid solution to neutralize toxic vapors and liquids in these high-risk environments, ensuring the safety of passengers and personnel. With its lightweight, easy-to-deploy design, the cylinder allows transportation authorities to quickly respond to chemical threats, minimizing disruption and protecting public health in enclosed spaces like trains, terminals, and baggage areas.

View All Products

In high-risk scenarios involving liquid spills, a rapid and effective response is crucial to ensure safety and minimize damage. FAST-ACT provides a comprehensive decontamination solution with products like the FAST-ACT Decontamination Powder, FAST-ACT Bulk Pail, Microfiber Towel Pack, Powder Bottle Pack, and Shaker Bottle. These products are designed to quickly neutralize and contain hazardous liquids, ensuring a safe and efficient response. FAST-ACT’s Decontamination Powder and delivery tools require minimal training, allowing teams to act swiftly when handling dangerous substances. Whether dealing with toxic chemicals or unknown liquids, FAST-ACT ensures spills are safely contained, neutralized, and cleaned, protecting both personnel and the environment.

LIQUID SPILLS

View All Products

In the critical realm of sensitive equipment decontamination, where protecting mission-essential assets is paramount, FAST-ACT offers a reliable, process-driven solution. FAST-ACT products, including FAST-ACT Puffer Bottle, Decontamination Mitts, and Decontamination Wipes, are designed to efficiently neutralize contaminants without compromising the equipment’s functionality. These products are easy to use, requiring minimal training, and can be deployed quickly in high-pressure situations. Whether the equipment is hardened or not, FAST-ACT ensures effective decontamination while preserving the integrity of sensitive assets, allowing teams to maintain operational readiness and mission success.

SENSITIVE EQUIPMENT

View All Products

Environmental remediation often involves the containment and neutralization of hazardous substances released into the air, soil, or water—ranging from hydrocarbon spills and battery byproducts to unknown chemical vapors. Rapid response and effective mitigation are critical to reducing environmental impact and ensuring worker and community safety.

FAST-ACT supports these efforts with a broad-spectrum dry chemical technology engineered to neutralize a wide array of chemical hazards encountered during remediation. It is effective against flammable hydrocarbons, corrosive gases from damaged batteries (such as sulfur dioxide and hydrogen fluoride), and volatile organic compounds (VOCs).

Unlike traditional absorbents, FAST-ACT works by actively neutralizing threats at the source—no water activation is required, and no hazardous runoff is produced. It is especially useful in water-adjacent zones, remote field operations, and cold-weather environments where conventional methods may be limited.

Deployed by response teams across industrial, environmental, and emergency sectors, FAST-ACT provides immediate vapor suppression and simplifies operations in complex remediation scenarios. Its ease of use and broad applicability make it a practical tool for field teams managing chemical hazards in unpredictable conditions.

ENVIRONMENTAL REMEDIATION

View All Products

As more people own electric cars and the total number on the road rises each year, fires with these cars and other electric vehicles that have lithium-ion batteries come with the concern of releasing toxic gases. While any vehicle fire does release toxic gases such as carbon monoxide (CO), hydrogen cyanide (HCN), hydrochloric acid (HCl) and polycyclic aromatic hydrocarbons (PAHs); hydrogen fluoride (HF) represents an additional scary difference between electric vehicles and conventional gas powder vehicles as it is very dangerous and can be absorbed through the skin and produced through the combustion of the electrolyte in the battery. Some of the toxic and dangerous chemical compounds in an EV fire include: Hydrogen fluoride (HF), Hydrogen chloride (HCl), Sulphur dioxide (SO2), Nitrogen dioxide (NO2), and Hydrogen Cyanide (HCN). These chemicals pose additional risks to those associated with the EV fire, including those responding to the event. FAST-ACT Pressurized Cylinders provide a much-needed, and simple response tool for harmful gases and airborne chemicals.

EV BATTERY FIRES

Vapor

During EV battery fires, harmful off-gases like hydrogen fluoride (HF) and sulfur dioxide (SO₂) can be released into the air, posing serious risks to responders and bystanders. FAST-ACT Pressurized Cylinders provide a rapid-deployment solution for these airborne threats. With a directional spray and fast vapor neutralization, the cylinders knock down corrosive gases in real time, reduce inhalation risk, and support quick containment of the vapor zone. No activation time. No water required. Just instant control where it’s needed most.

Spills

When battery electrolyte or associated fluids leak during or after an EV incident, it’s critical to neutralize and contain the liquid before it spreads. FAST-ACT’s dry-decon tools—including our neutralizing powder,decon mitts, and wipes—deliver fast and flexible response for liquid hazards neutralizes corrosive liquid spills on contact, prevents further environmental damage, and safe for hard surfaces and sensitive equipment. FAST-ACT delivers full-spectrum battery fire mitigation—keeping your team safer and your response smarter.

View All Products

FAST-ACT Decontamination Mitts provide Individual Protection with small portable decon mitts for immediate DECON of personal gear, articles, and even skin. The FAST-ACT Decontamination Mitt is a Class I medical device for dual use on surface and skin. The small device is easy to use by a layperson with minimal training. The compact form is ideal for transportation, storage, and on the go at the warfighter or responder level.

SKIN

View All Products

In the high-stakes realm of hazardous material management, particularly in the context of unknown powdery substances, the need for a systematic, end-to-end solution is paramount. The DEFEND Kit is an innovative breakthrough in this field that offers more than just tools - it presents a complete process-oriented solution. Lt has been meticulously designed to guide operators through every step in both managing and neutralizing substances like fentanyl and its derivatives.

The DEFEND Kit, which stands for Detection, Eradication, and FENtanyl Decontamination is a deeply integrated approach. The process is not just a series of actions but a strategic framework that equips operators with the knowledge, methodology, and tools to handle potentially hazardous substances easily, safely, and effectively.

With an OPERATOR-CENTRIC DESIGN, each component of the DEFEND Kit was craftily developed to meet the specific needs of those managing hazardous materials. The system's focus is on ensuring operators have the most efficient, safe, and effective tools at their disposal.