DOT HazMat Inspection Priorities: What PHMSA’s New Focus Means for Hazardous Materials Transport

The U.S. Department of Transportation (DOT), through the Pipeline and Hazardous Materials Safety Administration (PHMSA), has outlined updated DOT hazmat inspection priorities, signaling a more targeted and data-driven approach to oversight of hazardous materials transport.

As reported by HazmatNation, these priorities provide insight into where DOT will concentrate outreach, inspection activity, and enforcement based on historical incident data and compliance trends. For organizations involved in shipping, packaging, and handling hazardous materials, this update offers important clarity into regulatory focus areas and emerging risk considerations.

This blog summarizes what was shared publicly through HazmatNation and provides operational context based on FAST-ACT’s experience supporting emergency preparedness and response across transportation, industrial, and healthcare environments.

Understanding PHMSA’s Data-Driven Inspection Framework

According to HazmatNation, PHMSA’s updated framework is designed to better align outreach, DOT inspection efforts, and enforcement actions with areas that present the greatest safety risk. Rather than applying uniform oversight across all regulated entities, the agency is prioritizing activities and sectors where past incidents and violations have had higher consequences.

The original report, DOT Lays Out New Hazmat Inspection Priorities, details how this approach is intended to improve compliance while reducing incidents involving hazardous materials during transportation.

Outreach and Emergency Response Information as a Prevention Tool

One key element of the updated priorities is increased outreach to the regulated community. PHMSA has emphasized that improved understanding of hazmat handling regulations can play a meaningful role in preventing incidents before they occur.

This outreach focuses on:

- Proper classification of hazardous materials

- Appropriate packaging selection

- Clear shipper responsibilities under existing regulations

- Access to accurate emergency response information, including appropriate use of the emergency response guidebook

By emphasizing education alongside enforcement, DOT is reinforcing the role of preparedness in reducing transportation-related hazmat incidents.

For more information of hazardous material handling in transportation, read here.

Where DOT Hazmat Inspections Will Be Concentrated

Under the updated DOT hazmat inspection priorities, PHMSA will focus inspection resources on activities associated with elevated risk. These include:

- General hazardous materials shippers

- Cylinder manufacturing and requalification facilities

- Drum manufacturing and recertification operations

- Shippers with a history of significant violations

- Lithium battery shipments

- Undeclared or improperly declared hazardous materials, including those originating from e-commerce channels

These inspection efforts complement enforcement activities conducted by other DOT agencies, including the Federal Motor Carrier Safety Administration (FMCSA), which plays a role in enforcing hazardous materials requirements in highway transportation.

Enforcement Focus and Regulatory Burdens

PHMSA has indicated that enforcement actions will prioritize consistency, timeliness, and risk-based decision-making. The agency has also highlighted the use of data analytics to better identify patterns related to leaks, failures, and noncompliance.

Importantly, this approach reflects an effort to balance safety outcomes with regulatory burdens, focusing enforcement on violations that pose meaningful risk rather than purely administrative deficiencies. While not specific to pipeline safety laws, related concepts such as leak detection, incident prevention, and system reliability continue to inform DOT’s broader safety strategy.

Operational Implications Beyond Compliance

While the updated priorities are regulatory in nature, they reflect operational realities that many organizations already face during hazardous materials transport and handling.

Based on FAST-ACT’s experience supporting emergency response preparedness, recurring challenges aligned with these priorities include:

- Undeclared or improperly classified hazardous materials entering the transportation stream

- Packaging failures that lead to leaks or vapor releases

- Lithium battery incidents involving fire or chemical hazards

- Discovery of unknown or mixed materials during routine operations or inspections

These scenarios underscore why compliance alone may not fully address real-world risk.

Preparedness Considerations for Hazardous Materials Stakeholders

Even with robust compliance programs, organizations involved in hazardous materials transport often evaluate how they would respond if an incident occurred. Preparedness considerations may include:

- Immediate response to leaks or vapor releases

- Protection of personnel, facilities, and sensitive equipment

- Coordination of response actions within existing regulatory frameworks

These considerations apply across transportation, industrial environments, and hospitals where hazardous materials may be present.

FAST-ACT Tools as Examples of Emergency Response Support

In environments where hazardous materials are shipped, stored, or handled, FAST-ACT products are designed to support rapid response and decontamination during unexpected incidents.

Examples include:

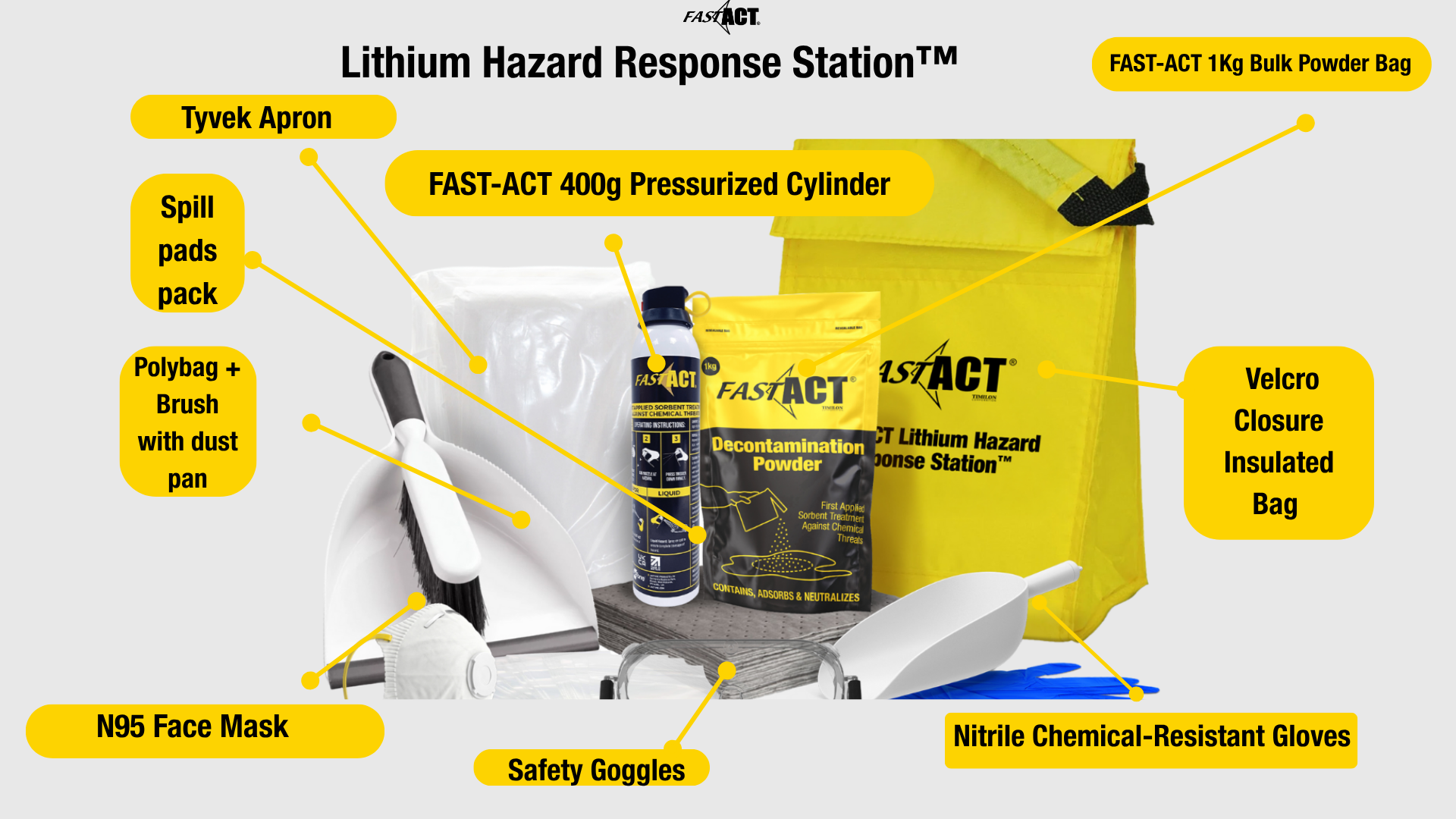

- FAST-ACT® Lithium Hazard Response Station™, safely neutralize chemical vapors and liquid spills without the use of water or complex procedures— minimizing exposure risk and operational disruption.

Learn more about FAST-ACT handling EV Battery Spills

- FAST-ACT® 400g Pressurized Cylinder, intended for immediate response to chemical spills and vapor releases through adsorption and decontamination

- FAST-ACT® Decontamination Mitt, used for rapid neutralization of hazardous agents on skin or surfaces. *CE classified as a class I medical device for use on skin and surfaces in the EU.

- FAST-ACT® Decontamination Wipes, designed for removal of chemical contaminants and radiological particles from skin and equipment. *CE classified as a class I medical device for use on skin and surfaces in the EU.

These tools are not regulatory compliance solutions. They are operational resources intended to support emergency response and exposure mitigation when incidents occur. Organizations seeking performance data, including testing in cold-weather environments or around sensitive equipment, can reach out to the FAST-ACT team directly for testing information and validation.

Final Perspective on DOT Hazmat Inspection Priorities

The updated DOT hazmat inspection priorities provide insight into how PHMSA is aligning oversight with measurable safety risk. For organizations involved in hazardous materials shipping and packaging, these priorities reinforce the importance of accurate classification, proper packaging, and preparedness for real-world incidents.

By understanding the direction outlined by the Hazardous Materials Safety Administration and aligning internal practices accordingly, companies can better manage both compliance expectations and operational risk. Reach out to the FAST-ACT team for test reports or information on our training program.

CE notice: FAST-ACT is CE-marked as a Class I medical device in the EU. References to dermal use apply only within EU regulatory scope. Outside the EU, FAST-ACT is not a medical treatment and is intended for contamination control and risk reduction only.

About Timilon Corporation:

Timilon Corporation is the manufacturer of FAST-ACT®, a proprietary formulation of non-toxic high-performance specialty materials effective at neutralizing a wide range of toxic chemicals with the added capability to destroy chemical warfare agents. The FAST-ACT technology is utilized by leading defense agencies, chemical industrial companies, first responders and HAZMAT teams to quickly and safely eliminate chemical hazards. For more information, reach out to Leticia Menzzano, Marketing Manager, lmenzzano@timilon.com.

FAQs

What are DOT hazmat inspection priorities?

DOT hazmat inspection priorities are focus areas identified by the Department of Transportation, through PHMSA, to guide inspections, outreach, and enforcement toward activities that present higher safety risk during hazardous materials transport.

Does FAST-ACT provide regulatory compliance solutions?

No. FAST-ACT products are designed to support emergency response and decontamination during hazardous materials incidents. They do not replace or fulfill regulatory compliance requirements.

How do DOT hazmat inspection priorities relate to FAST-ACT’s role in hazardous materials response?

The DOT hazmat inspection priorities highlight areas where hazardous materials incidents are more likely to occur, such as undeclared shipments, packaging failures, and lithium battery transport. FAST-ACT supports emergency response and exposure mitigation in these types of scenarios by providing rapid-deployment decontamination tools designed for use when hazardous materials are already present.

How does FAST-ACT fit into hazardous materials transport environments?

FAST-ACT products are used in transportation-related environments such as warehouses, shipping facilities, inspection areas, and receiving docks to support rapid response during hazardous materials incidents. These tools are intended to complement existing safety procedures and emergency response plans.

Has FAST-ACT been tested for use in challenging conditions?

FAST-ACT products have undergone testing for use in cold-weather environments and around sensitive equipment. Organizations can contact the FAST-ACT team to discuss available testing data and validated use cases.