Safe Hazardous Package Handling: Lithium, Opioids, and Chemical Spill Response

Every day, workers in shipping, delivery, and logistics handle thousands of packages — many of which may contain materials that are hazardous if leaked, spilled, or mishandled. While campaigns like USPS Hazmat Awareness Month help reinforce safety practices, incidents related to hazardous package handling can happen at any time of the year, from chemical spills to opioid exposure or lithium battery leaks.

Ensuring employee safety requires a combination of awareness, proper handling protocols, and practical chemical decontamination tools that can neutralize threats quickly.

Common Hazards in Hazardous Package Handling

Employees in logistics, mail facilities, and delivery services face a variety of risks, including:

Lithium battery leaks or fires

Lithium-ion batteries in electronics can leak or even ignite if damaged during shipping. These fires can escalate quickly, releasing toxic fumes and causing severe burns or facility damage.

Opioid and unknown powder exposures

Packages containing illegal or unknown powders, including opioids, pose serious inhalation and contact risks. Even small amounts can be dangerous to employees, requiring immediate containment and decontamination.

Corrosive liquids and chemical residues

Spills from chemicals or residues from leaking containers can cause skin irritation, respiratory issues, and contamination of surrounding packages or work areas. FAST-ACT is designed to neutralize a variety of chemical threats, including hydrogen peroxide, chlorine dioxide, hypochlorous acid, and sodium gluconate, making it ideal for these scenarios.

Chemical vapors

Some hazardous substances may release fumes that are not immediately visible. Prolonged exposure to chemical vapors can affect the nervous, digestive, or immune systems, highlighting the need for rapid response tools and an effective decontamination process.

Understanding these risks is the first step toward safer hazardous package handling.

FAST-ACT Solutions for Safe Hazardous Package Handling

FAST-ACT provides a range of ready-to-use chemical decontamination solutions to help employees respond safely and efficiently to package-related hazards:

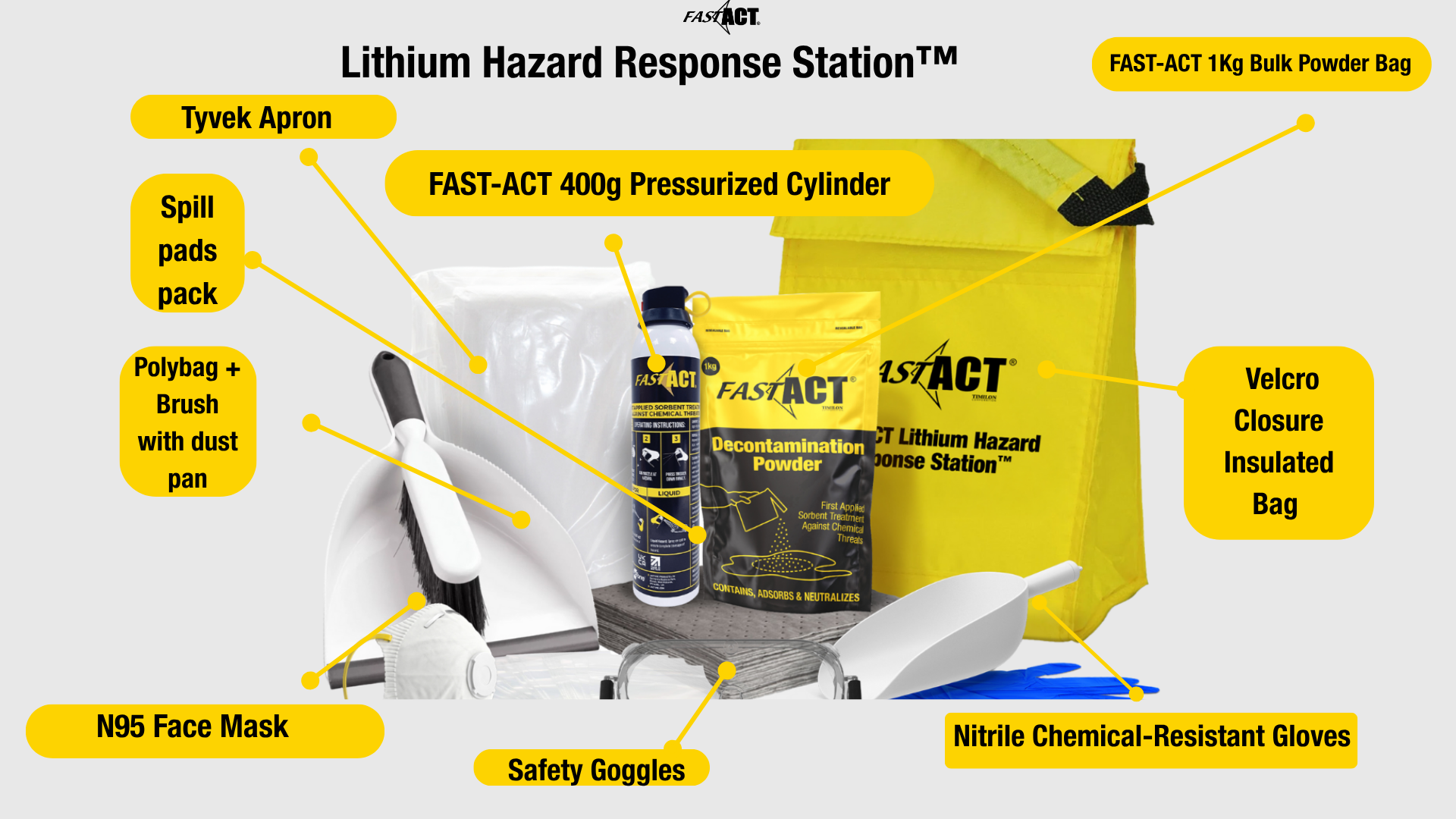

- FAST-ACT Lithium Hazard Response Station – An all-in-one solution to protect facilities from lithium-ion battery failures. It safely neutralizes toxic gases and electrolyte spills from drops, punctures, or thermal runaway without water or complex procedures, minimizing exposure risk and operational disruption.

- FAST-ACT DEFEND Kit – A comprehensive fentanyl decontamination solution that provides tools for quick detection and thorough decontamination, ensuring employee safety during opioid or unknown powder incidents. Ideal for law enforcement, emergency response, and hazardous package handling scenarios.

- FAST-ACT Pressurized Cylinders – The 400G Pressurized Cylinder is an essential tool for immediate response and management of hazardous chemical spills and vapors. Engineered with the innovative FAST-ACT® pressurized technology, this 400g cylinder provides a rapid and efficient solution for the adsorption and decontamination of toxic chemical vapors or liquids, making it imperative for safe and effective emergency response.

These solutions are easy to deploy, require no mixing, and can be used by any employee, making them practical for daily operations and emergency incidents alike. Chemical indicators or visual cues can help staff quickly identify potential hazards and apply the most adequate FAST-ACT product during the decontamination process.

Best Practices for Hazardous Package Handling Safety

Alongside practical tools, organizations should implement structured safety protocols to protect employees:

- Recognize warning signs

Check packages for hazard labels, damaged packaging, or unusual odors. Encourage employees to report suspicious packages immediately.

- Use PPE and chemical decontamination tools

Whenever a package is suspected of containing hazardous materials, employees should use proper personal protective equipment and deploy FAST-ACT products to neutralize hazards quickly.

- Contain and isolate

Contain spills immediately using absorbent materials or kits like the FAST-ACT Decontamination Powder, and isolate the area to prevent contamination from spreading.

- Train employees regularly

Hands-on training in chemical and opioid response, coupled with ready-to-use FAST-ACT products, improves confidence and safety during real incidents.

Maintaining Year-Round Hazardous Package Handling Preparedness

Hazardous package handling risks don’t stop after awareness campaigns. Organizations need to ensure:

- Constant readiness with accessible decontamination tools

- Employee and Customer awareness and regular refresher training

- Incident reporting and follow-up protocols

By integrating FAST-ACT Dry Decontamination Solutions into daily operations, companies can reduce response time, limit exposure, and maintain operational continuity in hazardous package handling.

Enhance Hazardous Package Handling Safety

Hazardous package handling is an ongoing concern for logistics, delivery, and mail facilities. By combining awareness campaigns, proper safety protocols, and practical chemical decontamination solutions like the FAST-ACT Lithium Hazard Response Station, FAST-ACT DEFEND Kit, FAST-ACT Pressurized Cylinders, and FAST-ACT Shaker Bottle, organizations can empower employees to respond safely and effectively to chemical, lithium, or opioid-related incidents.

Contact us today to learn more about how FAST-ACT products can enhance your hazardous package handling safety program.

About Timilon Corporation:

Timilon Corporation is the manufacturer of FAST-ACT®, a proprietary formulation of non-toxic high-performance specialty materials effective at neutralizing a wide range of toxic chemicals with the added capability to destroy chemical warfare agents. The FAST-ACT technology is utilized by leading defense agencies, chemical industrial companies, first responders and HAZMAT teams to quickly and safely eliminate chemical hazards. For more information, reach out to Leticia Menzzano, Marketing Manager, lmenzzano@timilon.com.

FAQs

What are the primary hazards in hazardous package handling for shipping and mail facilities?

The main hazards include lithium-ion battery leaks or thermal runaway, fentanyl or unknown powder exposures, corrosive liquid spills, and toxic chemical vapors. These risks can lead to respiratory harm, chemical burns, and facility contamination, making proper hazardous package handling procedures essential for worker safety.

How should employees respond to a lithium-ion battery leak or damaged battery package?

Employees should immediately isolate the package, avoid water, and use a lithium battery decontamination tool such as the FAST-ACT Lithium Hazard Response Station. This tool neutralizes toxic gases and electrolyte spills from punctured or overheating lithium-ion batteries, helping prevent fires, toxic fumes, and facility downtime.

What is the safest way to handle packages suspected of containing fentanyl or unknown powders?

If a package may contain opioids or unidentified powders, employees should avoid handling, wear proper PPE, and secure the area. A fentanyl decontamination solution like the FAST-ACT DEFEND Kit provides rapid detection and neutralization, reducing inhalation and skin-contact risks during opioid-related package incidents.

How does FAST-ACT improve chemical spill and vapor response during hazardous package handling?

FAST-ACT products—including the FAST-ACT 400G Pressurized Cylinder and FAST-ACT Decontamination Powder—rapidly adsorb and neutralize toxic chemical liquids and vapors. These tools are ideal for hazardous package handling because they work instantly, require no mixing, and support safer response to chemicals such as hydrogen peroxide, chlorine dioxide, hypochlorous acid, and other hazardous residues.

What hazardous package handling safety protocols should organizations follow year-round?

Organizations should train employees to spot hazard indicators, use PPE, isolate spills quickly, and keep chemical decontamination tools accessible. Incorporating FAST-ACT Dry Decontamination Solutions into daily operations reduces exposure risk, accelerates response time, and strengthens year-round preparedness for lithium, chemical, and opioid package hazards.