Understanding Lithium-Ion Battery Chemical Hazards: What Recent Incidents Teach Us About Preparedness

When lithium-ion battery failures occur—whether in electric bikes, power banks, solar panel systems, electric scooters, or industrial energy storage—most attention focuses on flames or fire risks. But responders and safety professionals know the real threat extends far beyond ignition.

Large lithium batteries involved in thermal runaway events can release highly toxic gases and corrosive liquids, creating chemical hazards that persist long after fire incidents are controlled.

Recent large-scale incidents, including the LA lithium-ion battery fire cleanup highlighted by the Emergency Management Division, reinforced an operational truth: Lithium-ion battery failures are chemical incidents—and chemical incidents require chemical mitigation tools. This blog explores why battery failure produces dangerous hazardous fumes, how these events escalate into hazardous areas, and why emergency response personnel need fast, water-free neutralization methods to reduce chemical exposure.

Why Lithium-Ion Battery Failures Create Dangerous Chemical Hazards

During thermal runaway, puncture, damaged rechargeable lithium-ion battery cells, or faulty manufacturing, lithium batteries can release a mixture of toxic gases and corrosive liquid electrolyte. These reactions are driven by the high energy density inside Li-ion batteries, especially those using lithium cobalt oxide or Lithium Metal chemistries.

Documented emissions include:

- Phosphorus-containing decomposition products

- Liquid electrolyte spills that create hazardous waste

These emissions represent severe chemical exposure risks:

- HF is associated with human toxicity potential even at very low concentrations

- Hazardous fumes and vapors contribute to emission to air that spreads through enclosed spaces

- Electrolyte spills contaminate floors, tools, and battery-powered devices

- Off gassing can continue during movement of damaged cells or spare batteries

These hazards appear across all types of Li-ion batteries, including lithium polymer (Li-Po), smartphone batteries, and large-format energy systems.

Lessons From LA Lithium-Ion Battery Fire Cleanup

As described in the Emergency Management Division’s post, the LA lithium-ion battery fire cleanup was one of the largest in U.S. history. While FAST-ACT does not comment on cleanup techniques, the event underscored a nationwide trend:

Lithium-ion incidents are increasing in frequency across consumer and industrial settings.

Electric bikes, solar energy storage, and battery-powered devices expand the number of hazardous areas where thermal runaway can occur. When it does, the dominant risk is not simply fire and explosion—it is the release of toxic chemicals requiring immediate mitigation.

How FAST-ACT Supports Response to Lithium-Ion Battery Chemical Hazards

FAST-ACT provides dry, water-free chemical mitigation tools designed specifically to neutralize toxic vapors and liquid chemical spills. These solutions are essential in lithium-ion battery incidents because water alone cannot neutralize HF, SO₂, HCl, or corrosive electrolyte hazards.

Learn why dry decontamination solutions are critical.

Below are the FAST-ACT tools most relevant to lithium-ion battery chemical hazards and Emergency Response operations.

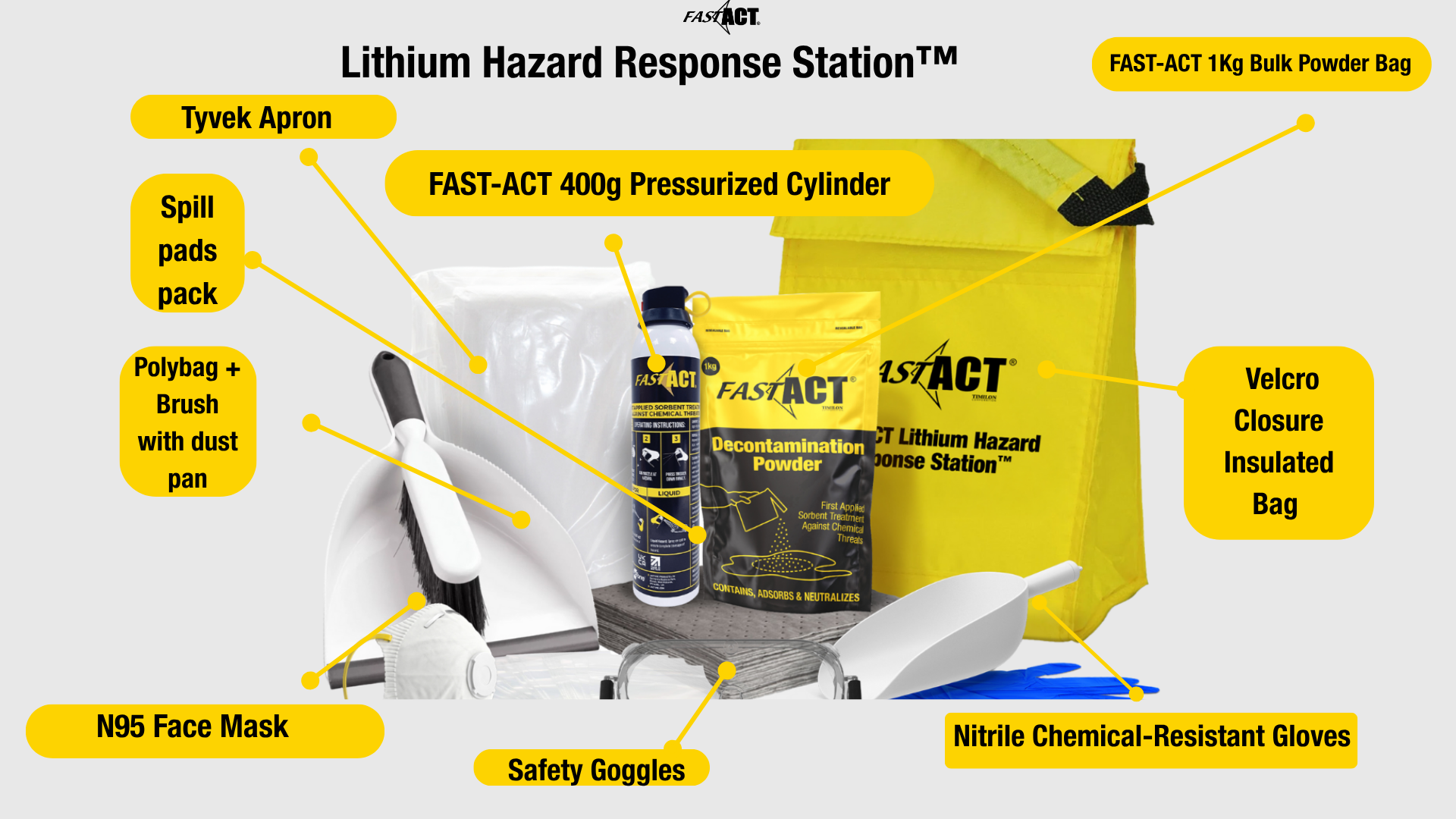

FAST-ACT® Lithium Hazard Response Station™

An all-in-one solution designed for lithium-ion battery chemical hazards.

- Neutralizes airborne vapors

- Adsorbs corrosive electrolyte spills

- No water required—safe for electronics, battery rooms, and charging areas

- Reduces chemical exposure risk in fire incidents and post-event processing

Ideal for manufacturing, recycling, warehousing, and emergency response environments.

FAST-ACT® Pressurized Cylinders (400g, 1kg, 2kg, 4kg)

FAST-ACT® Pressurized Cylinders provide a scalable, rapid-deployment solution for neutralizing toxic vapors released during lithium-ion battery failures and thermal runaway events. Designed for Emergency Response operations and industrial battery environments, these cylinders deliver immediate vapor mitigation without water or complex setup.

Across all sizes, the cylinders:

- Neutralize toxic vapors generated during off-gassing events

- Support emergency response personnel working in hazardous areas

- Provide controlled discharge through a user-friendly plastic valve

- Include a safety clip for secure handling

- Require no maintenance—simply shake before and during use

- Are effective near damaged lithium-ion batteries, power banks, EV systems, and battery-powered devices

FAST-ACT® Dry Decontamination Powder (1kg Bag) and FAST-ACT® Bulk Pail (5kg)

FAST-ACT® Dry Decontamination Powder products provide fast, water-free neutralization of corrosive liquids and electrolyte spills generated during lithium-ion battery failures and thermal runaway events. These dry decontamination options offer flexible coverage for both small spills and large-area contamination.

Across both formats, FAST-ACT® Powder products:

- Neutralize corrosive liquids, electrolyte leaks, and hazardous waste

- Require no water, making them safe for use around sensitive electronics

- Support compliant handling of dangerous goods

- Are effective in labs, EV service centers, repair facilities, recycling operations, and industrial lithium battery environments

- Provide reliable coverage anywhere Li-ion batteries are handled, stored, or tested

Essential for facilities storing large Li-ion batteries or managing aging of batteries.

Why Preparedness Is Critical for Lithium-Ion Battery Fires

Recent fire incidents involving lithium-ion batteries—from smartphones to industrial storage—demonstrate a critical truth: Chemical Hazards created during thermal runaway must be addressed immediately.

Being prepared with fast, reliable dry decontamination tools allows teams to:

- Reduce hazardous fumes

- Control chemical exposure

- Protect emergency response personnel

- Support Safe Handling Practices

- Maintain compliance with regulatory limits

- Prevent escalation into larger hazardous areas

FAST-ACT provides the tools responders need to manage these hazards confidently.

Download our full resource on how FAST-ACT supports Emergency Response teams addressing lithium-ion battery chemical hazards or reach out to our team for more information and test reports.

About Timilon Corporation:

Timilon Corporation is the manufacturer of FAST-ACT®, a proprietary formulation of non-toxic high-performance specialty materials effective at neutralizing a wide range of toxic chemicals with the added capability to destroy chemical warfare agents. The FAST-ACT technology is utilized by leading defense agencies, chemical industrial companies, first responders and HAZMAT teams to quickly and safely eliminate chemical hazards. For more information, reach out to Leticia Menzzano, Marketing Manager, lmenzzano@timilon.com.

FAQs

What chemical hazards are released during lithium-ion battery thermal runaway events?

Lithium-ion battery failures and thermal runaway events can release hazardous chemicals such as hydrogen fluoride (HF), sulfur dioxide (SO₂), hydrogen chloride (HCl), and corrosive liquid electrolyte. These vapors and liquids create significant chemical exposure risks for Emergency Response personnel and facilities handling lithium batteries.

How can Emergency Response teams neutralize toxic vapors from lithium-ion battery failures?

Emergency Response teams can neutralize toxic vapors using dry decontamination tools like FAST-ACT® Pressurized Cylinders, which adsorb and neutralize airborne chemical hazards without the need for water or complex setup. These tools are useful during off-gassing, battery failure, and thermal runaway events.

What tools are effective for managing electrolyte leaks from damaged lithium batteries?

Dry decontamination products such as FAST-ACT® Dry Decontamination Powder and the FAST-ACT® Bulk Pail neutralize corrosive electrolyte spills and hazardous waste from lithium-ion battery incidents. These tools are effective in labs, EV service centers, manufacturing facilities, and industrial lithium battery environments.

Why is dry decontamination important for lithium-ion battery incidents?

Dry decontamination is important because water does not neutralize HF, HCl, or corrosive electrolyte released during battery failure. Water can also be unsafe around sensitive electronics. FAST-ACT® provides water-free mitigation for vapor and liquid chemical hazards, making it suitable for hazardous areas and battery-powered device environments.

How can facilities improve preparedness for lithium-ion battery chemical hazards in their region?

Facilities can improve preparedness by training staff on lithium-ion chemical hazards, equipping their Emergency Response teams with dry decontamination tools, and implementing Safe Handling Practices for battery storage, charging, and recycling. FAST-ACT® solutions help facilities meet regulatory limits and protect personnel from hazardous fumes and corrosive spills.