Why Effective Chemical Spill Response Matters in Industrial Settings

Introduction: When a Spill Becomes a Safety Emergency

Chemical spills are more than an inconvenience—they’re a hazardous material spill that threatens health and safety. Recent spill events at a U.S. battery plant sent workers to the hospital, a reminder that even a potential spill can escalate into a crisis. Without clear planning and the right spill response materials, facilities risk serious health risks for employees, costly downtime, and regulatory noncompliance.

In the sections below, we’ll look at several industries where chemical spills are a pressing concern—including lithium-ion battery facilities, mining operations, and transportation hubs such as airports and ports—and explore how the right tools and response strategies can protect workers, reduce risks, and keep operations running safely.

The High-Stakes Reality of Lithium-Ion Battery

In the fast-growing world of battery production, storage, and transportation, hazardous chemicals are part of daily operations. Electrolytes and solvents used in cell manufacturing can trigger fires, release toxic gases, or damage equipment. During a spill event, workers may face exposure to hydrogen fluoride, sulfur dioxide, or other high-hazard level chemicals.

Lithium-ion battery incidents are becoming more common as industries rely heavily on this technology for energy storage, production, and transport. A dropped cell, punctured pack, thermal runaway, or even mechanical damage can quickly turn into a serious hazard. These failures often release toxic gases and corrosive electrolyte leaks, creating both immediate safety risks for workers and operational challenges for facilities.

The risks aren’t hypothetical. Recently, emergency crews were dispatched to a U.S. battery plant after a chemical spill led to multiple workers being hospitalized for evaluation. Incidents like this highlight how quickly a single failure—whether from a dropped cell, punctured pack, thermal runaway, or mechanical damage—can escalate. These events often release toxic gases and corrosive electrolyte leaks, creating immediate safety risks for workers and serious operational challenges for facilities.

Lessons Learned from Recent Incidents

- Preparedness is critical. Facilities must anticipate battery-related failures and ensure they have the tools and training to respond immediately.

- Traditional spill response isn’t enough. Absorbent materials and water-based cleanup methods are too slow or unsafe for volatile electrolytes and vapor releases.

- Worker protection must go beyond PPE. While personal protective equipment is essential, teams also need fast, dry neutralization methods to reduce exposure risks.

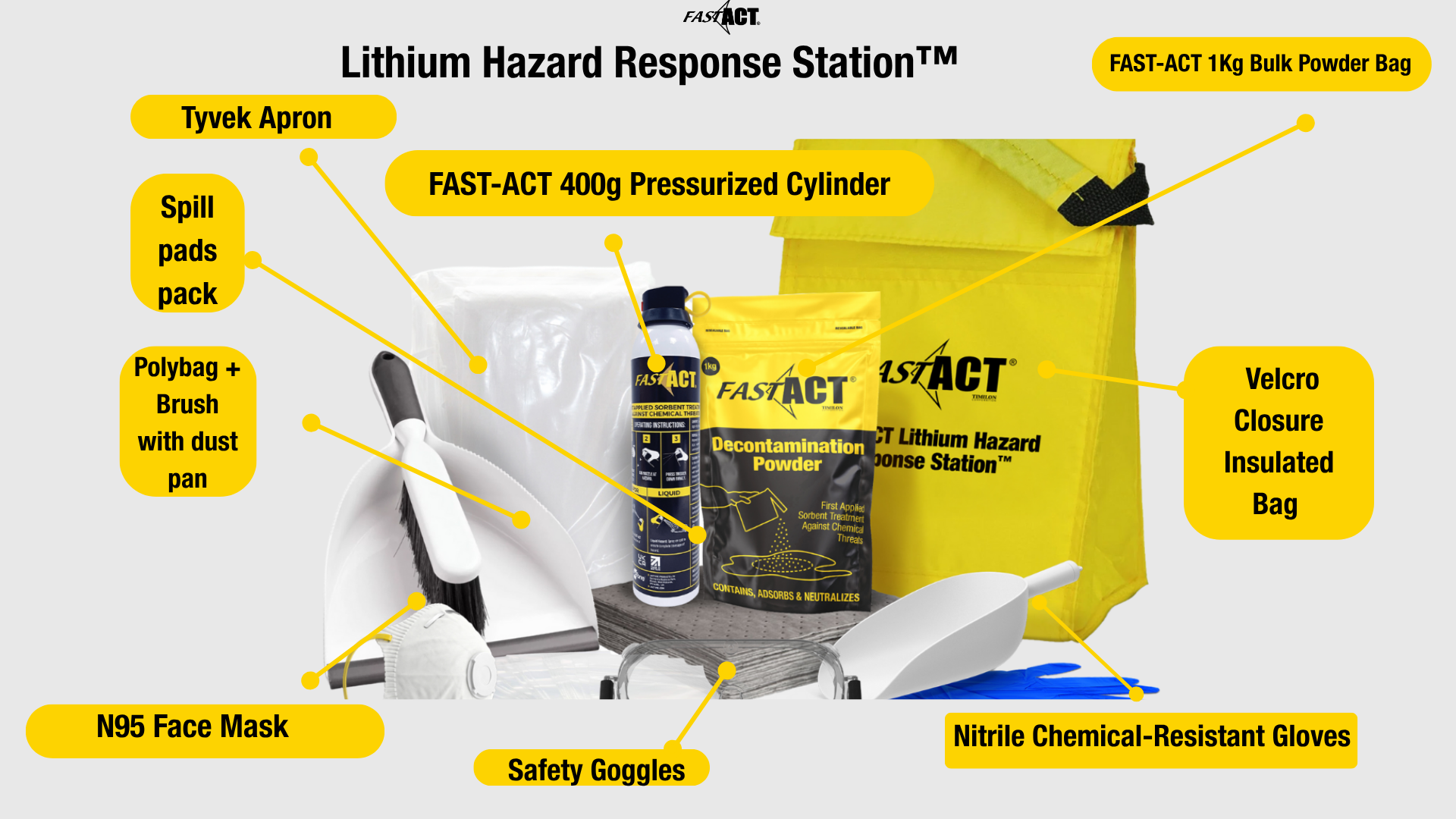

Spill cleanup in these environments requires more than just standard absorbent materials—it demands rapid neutralization. That’s where FAST-ACT comes in. The FAST-ACT Lithium Hazard Response Station™ provides a streamlined approach to emergency response. Instead of relying on water or complicated cleanup procedures, the station equips teams to quickly neutralize airborne vapors and liquid spills on-site. This not only minimizes exposure risks but also helps reduce downtime—allowing operations to continue safely and with confidence.

Mining and Underground Operations: A Confined-Space Challenge

Mining operations face unique potential hazards, including corrosive acids and solvents that can leak in tunnels or shafts. Confined spaces make spill containment and ventilation especially difficult, and without quick action, hazardous waste and hazardous spills can contaminate soil and water, creating long-term environment, health & safety risks.

FAST-ACT solutions like the Bulk Pail or Immediate High Contamination Density Kit allow teams to act quickly in these environments. By neutralizing both liquid spills and vapor hazards, these tools help protect miners, reduce contamination risks, and support compliance with chemical spill planning and response requirements—all while keeping operations moving safely.

Airports and Ports: Critical Hubs for Hazardous Material Movement

Airports and maritime ports are essential gateways for the transport of lithium-ion batteries and other hazardous chemicals. But these hubs also face heightened risks—whether it’s a leaking shipment in a cargo hold, a chemical spill on a loading dock, or vapors released during transit. With high volumes of goods moving daily, even a single spill event can disrupt operations, create serious health risks, and threaten public safety.

Real-World Example: Recently, a cargo shipment containing improperly declared lithium-ion batteries caught fire at a U.S. facility after being shipped from overseas. The fire risk was increased due to inadequate packaging and lack of proper containment, which triggered regulatory action.

Lessons Learned from this Incident

- Packaging & declaration matter. When batteries are shipped without proper labeling or containment, the chance of fire or smoke increases significantly.

- Speed of detection & containment is key. Delays in recognizing that a cargo package is overheating or releasing vapors allow hazards to spread. Emergency response tools must be immediately accessible.

- Training & safety systems cannot be overlooked. Cargo handlers, airport staff, and logistics teams need clear protocols for inspecting, storing, and responding to battery shipments.

- Regulatory compliance supports safety. Ensuring shipments meet hazardous materials shipping standards helps reduce risk, but having tools for on-site neutralization or containment is also critical.

Relying on traditional wet decontamination isn’t always possible in these environments, especially where water use is restricted or where spills involve reactive chemicals. Instead, rapid, dry neutralization is key. FAST-ACT provides airports and ports with scalable tools to manage these incidents effectively:

- The FAST-ACT Bulk Pail and FAST-ACT Shaker Bottle deliver immediate neutralization for spills on cargo floors, docks, or storage areas.

- The FAST-ACT Pressurized Cylinder offers fast vapor suppression inside aircraft cargo bays, shipping containers, or warehouses.

- For personnel who may be directly exposed, FAST-ACT Decontamination Mitts and FAST-ACT Decontamination Wipes provide quick, skin-safe treatment without water.

- The FAST-ACT DEFEND Kit is used for the deactivation of opioids and synthetic opioids “fentanyl”.

By equipping spill response teams at airports and ports with these products, operators can reduce downtime, improve compliance with OSHA spill response guidelines, and protect workers while keeping supply chains moving.

Building a Safer Spill Response Plan

For any facility handling hazardous chemicals, a comprehensive spill response plan is essential. This plan should include:

- A thorough risk assessment to identify potential hazards

- Clear access to spill response kits stocked with the right spill control materials

- Worker training using safety data sheets and spill response checklist drills

- Partnerships with local emergency services for coordinated spill event response

By integrating FAST-ACT’s spill response kits and absorbent materials, companies can strengthen their Environment, Health, and Safety (EHS) programs while also maintaining compliance with Occupational Safety and Health Administration (OSHA) requirements.

Conclusion: Safety Starts with Readiness

Every spill event is a test of a company’s preparedness. Whether in a mine, battery plant, airport, or port response scenario, hazardous materials demand speed and readiness. A single hazardous material spill can expose workers to dangerous health risks, disrupt operations, and harm the surrounding environment.

By investing in proper spill prevention, maintaining spill response materials, and equipping workers with both personal protective equipment and other decontamination solutions, facilities can ensure they are ready for any chemical spill response. When it comes to hazardous spills, speed and preparation make all the difference.

Contact our team today to schedule a consultation or request more information. Together, we can protect your people, your operations, and your community.

About Timilon Corporation:

Timilon Corporation is the manufacturer of FAST-ACT®, a proprietary formulation of non-toxic high-performance specialty materials effective at neutralizing a wide range of toxic chemicals with the added capability to destroy chemical warfare agents. The FAST-ACT technology is utilized by leading defense agencies, chemical industrial companies, first responders and HAZMAT teams to quickly and safely eliminate chemical hazards. For more information, reach out to Leticia Menzzano, Marketing Manager, lmenzzano@timilon.com.

FAQs

What makes lithium-ion battery spills so hazardous?

Lithium-ion battery failures can release toxic gases such as hydrogen fluoride and corrosive electrolyte leaks. These hazards pose immediate health risks to workers and can escalate into fires, smoke events, or thermal runaway if not neutralized quickly.

Why isn’t traditional spill response enough for battery electrolytes and chemical vapors?

Standard absorbents and water-based cleanup methods are often too slow or unsafe. Many electrolytes react with water, and vapors spread quickly in enclosed spaces. Dry neutralization provides faster, safer control during a chemical spill event.

How does FAST-ACT support spill response in battery manufacturing and energy storage facilities?

FAST-ACT products neutralize airborne vapors and liquid electrolyte spills on contact, helping facilities reduce exposure risks, maintain compliance, and limit operational downtime. The Lithium Hazard Response Station™ is specifically designed for lithium-ion environments.

How can airports and maritime ports improve spill response readiness?

Equipping response teams with rapid, dry neutralization tools—such as the FAST-ACT Pressurized Cylinder, Bulk Pail, and Shaker Bottle—enables faster containment of spills on cargo floors, docks, and inside aircraft or shipping containers.

Can FAST-ACT be used alongside PPE and traditional decontamination systems?

Yes. PPE protects workers, while FAST-ACT neutralizes chemical residues, vapors, and spills. Dry decontamination complements traditional wet systems and enhances overall site safety during a hazardous material spill.