Dry Decontamination in Cold Weather: Managing Chemical and Vapor Hazards When Temperatures Drop

Extreme cold weather creates a significant cold weather challenge for hazardous materials response. When chemical spills, chemical releases, or vapor threats occur in cold-weather environments, traditional decontamination methods—especially water-based decontamination—can become ineffective or unsafe.

Dry decontamination in cold weather provides an alternative approach that supports emergency decontamination when freezing risk and ambient conditions limit conventional options.

The Cold Weather Challenge of Chemical and Vapor Decontamination

Cold-weather environments complicate the decontamination process due to temperature-related limitations and safety concerns.

Common challenges include:

- Freezing risk affecting hoses, pumps, and water showers

- Ice formation caused by runoff from water-based decontamination

- Delays in establishing a decontamination line

- Slip and fall hazards around decontamination stations

- Reduced effectiveness in extremely cold temperatures

- Increased uncertainty during hazardous chemical incidents involving unknown substances

Why Dry Decontamination in Cold Weather Is Essential

Dry decontamination in cold weather eliminates many of the limitations associated with liquid-based systems.

Key advantages of dry decontamination include:

- No reliance on water or temperature-sensitive infrastructure

- Faster emergency decontamination in cold-weather environments

- Reduced spread of particulate contaminants

- Safer working conditions for hazmat responders

- Effective mitigation of liquid chemical spills and hazardous vapors

FAST-ACT® Technology and Cold-Weather Performance

FAST-ACT technology is designed to function across a wide range of ambient conditions, including extremely cold temperatures. FAST-ACT dry decontamination products were evaluated through independent, third-party testing to assess functionality and performance in extreme cold conditions. Testing was conducted by an accredited laboratory in accordance with NATO AECTP-230 climatic standards under C2 Cold conditions.

Test Conditions

The evaluation was performed in a controlled climatic chamber at temperatures ranging from −37°C to −46°C (−34.6°F to −50.8°F), with an average test temperature of approximately −45°C. FAST-ACT materials were acclimatized to these conditions prior to testing, and a reference water sample was fully frozen at test initiation, confirming that conditions exceeded the operational limits of water-based decontamination systems.

Test Scope

Testing evaluated both functional integrity and decontamination performance of FAST-ACT dry decontamination powder and pressurized cylinder delivery systems against representative liquid and vapor threats, including:

- 35% sulfuric acid (H₂SO₄)

- Dimethyl methylphosphonate (DMMP)

- Chlorine gas (generated during testing)

Key Findings

- FAST-ACT powder remained physically stable and usable at −45°C

- Immediate adsorption and neutralization of liquid chemical threats was observed

- Pressurized cylinders functioned normally after extended cold exposure

- Effective neutralization of chlorine gas under test conditions

- Performance maintained despite conditions where water-based decontamination systems were inoperable

Test Conclusion

The final test report concluded that FAST-ACT remained fully functional against both liquid and vapor chemical threats under NATO C2 Cold conditions. Results demonstrate that dry decontamination using FAST-ACT is viable in extreme cold environments where water-based decontamination methods are ineffective or unavailable

FAST-ACT® Dry Decontamination Powder in Cold Weather

The FAST-ACT® Dry Decontamination Powder provides a practical solution for managing chemical spills in cold-weather environments where water-based decontamination may be ineffective or unsafe. As an absorbent powder, it is designed to rapidly contain and neutralize chemical contaminants without relying on water, making it suitable for use in freezing and sub-zero conditions.

Packaged in a 1kg bag, the powder supports flexible deployment across laboratories, field hazmat response operations, and emergency scenarios. Its dry formulation allows responders to initiate emergency decontamination without water showers or fixed infrastructure, reducing freezing risk while enabling faster containment and hazard stabilization in cold-weather conditions.

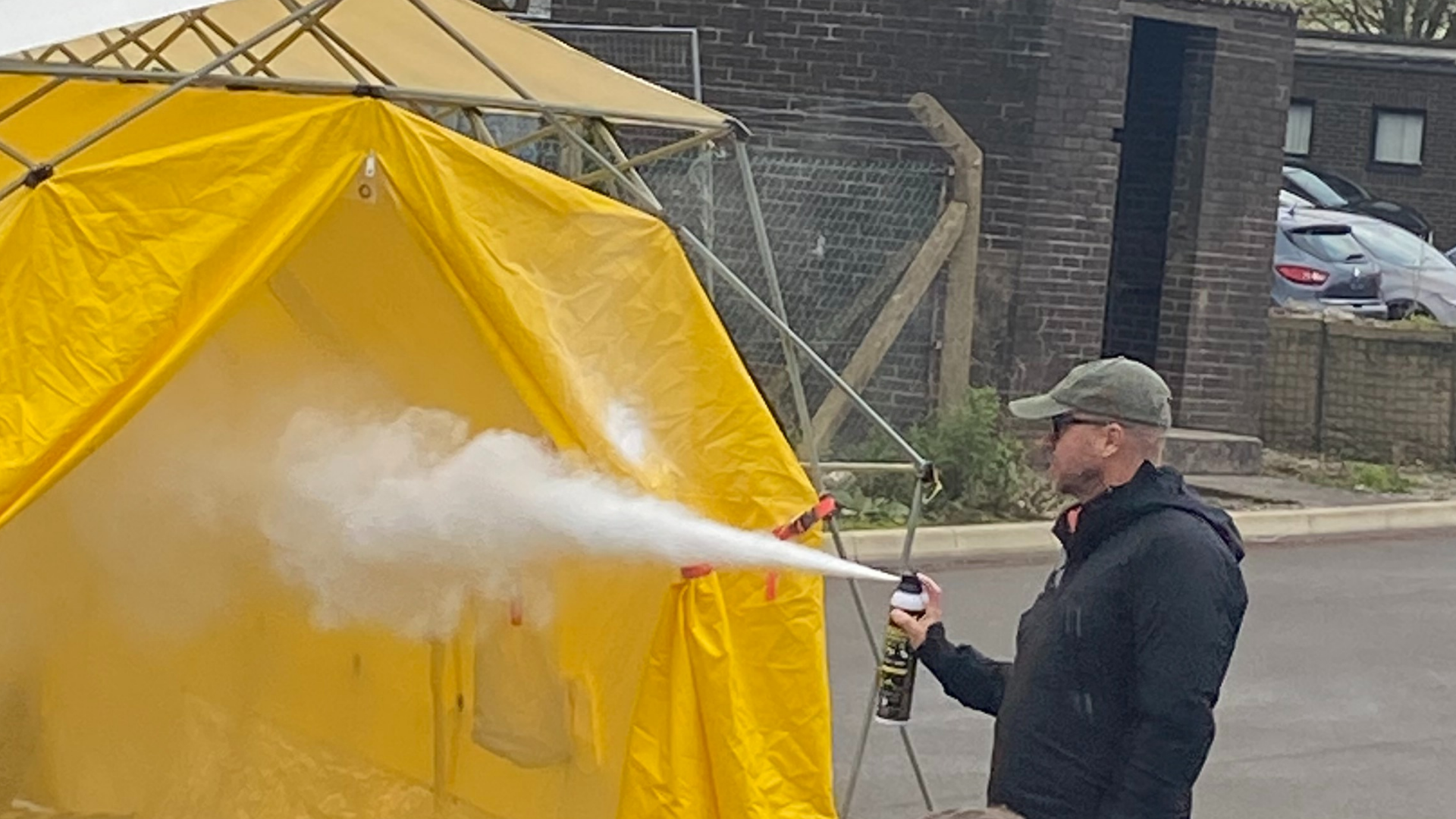

FAST-ACT® Pressurized Cylinders for Vapor Threats

The FAST-ACT® Pressurized Cylinder supports rapid mitigation of hazardous vapors and liquid chemical releases.

Capabilities include:

- Controlled deployment for vapor threats and chemical spills

- No reliance on water-based decontamination

- Effective in cold-weather environments

- Available sizes: 400g, 1kg, 2kg, and 4kg

- Adaptable for varying exposure levels and incident scales

Dry Decontamination in Cold Weather for Hospital Preparedness

Hospitals must often perform emergency decontamination before patients enter the facility, particularly during hazardous chemical incidents in winter conditions.

Cold-weather hospital considerations include:

- Patients arriving before a decontamination line is established

- Decontamination required in exterior ambient conditions

- Freezing risk associated with water showers

- Limited space for permanent decontamination stations

Dry decontamination supports hospital protocols by:

- Enabling rapid decontamination outside hospital entrances

- Reducing secondary contamination inside facilities

- Supporting Standard Operating Procedures during cold-weather decontamination

- Allowing faster patient throughput without water-based systems

Industrial Applications of Dry Decontamination in Cold Weather

Industrial sites face year-round exposure to chemical threats, including during winter operations.

Common industrial cold-weather challenges include:

- Chemical spills in outdoor or semi-enclosed areas

- Disrupted water-based decontamination due to freezing temperatures

- Increased operational risk during hazardous chemical incidents

Dry decontamination benefits industrial environments by:

- Supporting immediate hazmat response without water

- Reducing downtime during chemical releases

- Enabling safe decontamination in cold-weather environments

- Maintaining operational continuity during emergency decontamination

Dry vs. Water-Based Decontamination in Cold Weather

Conclusion: Cold-Weather Decontamination Requires Adaptable Solutions

Chemical threats do not pause in winter. Incorporating dry decontamination into decontamination protocols and standard operating procedures improves readiness across healthcare and industrial environments.

FAST-ACT® technology provides a temperature-resilient approach to emergency decontamination, helping organizations manage chemical spills and vapor threats safely when water-based decontamination is not viable.

CE notice: FAST-ACT is CE-marked as a Class I medical device in the EU. References to dermal use apply only within EU regulatory scope. Outside the EU, FAST-ACT is not a medical treatment and is intended for contamination control and risk reduction only.

About Timilon Corporation:

Timilon Corporation is the manufacturer of FAST-ACT®, a proprietary formulation of non-toxic high-performance specialty materials effective at neutralizing a wide range of toxic chemicals with the added capability to destroy chemical warfare agents. The FAST-ACT technology is utilized by leading defense agencies, chemical industrial companies, first responders and HAZMAT teams to quickly and safely eliminate chemical hazards. For more information, reach out to Leticia Menzzano, Marketing Manager, lmenzzano@timilon.com.

FAQs

What is dry decontamination in cold weather?

Dry decontamination in cold weather refers to the use of non-water-based materials to adsorb and neutralize chemical contaminants when freezing temperatures make water-based decontamination impractical or unsafe. This approach reduces freezing risk and allows faster response in winter conditions.

Why is water-based decontamination challenging in extreme cold?

n freezing and sub-zero environments, water-based decontamination systems can freeze, create ice hazards, and delay response efforts. Runoff from water showers can also increase slip risks and complicate scene control, particularly during outdoor operations.

Has FAST-ACT® been tested in extreme cold temperatures?

FAST-ACT products have been independently tested by a third-party laboratory under NATO AECTP-230 C2 Cold conditions. Testing was conducted at temperatures ranging from −37°C to −46°C, confirming functionality in extreme cold environments.

Is dry decontamination suitable for hospital use in winter conditions?

Yes. Dry decontamination is commonly used in hospital preparedness planning to reduce contamination before patients enter the facility, particularly when outdoor decontamination is required and water-based systems pose freezing risks.

Does dry decontamination replace wet decontamination?

Dry decontamination does not replace wet decontamination in all scenarios. Instead, it serves as a complementary or initial response method, particularly when environmental conditions limit the effectiveness of water-based decontamination.