This blog summarizes what was shared publicly through HazmatNation and provides operational context based on FAST-ACT’s experience supporting emergency preparedness and response across transportation, industrial, and healthcare environments.

Tag: industry safety

National Environmental Awareness Month: Strengthening Environmental Chemical Hazard Response Across Industrial Operations

This blog will cover how key industries—including mining, oil and gas, environmental remediation, and battery manufacturing—manage chemical hazards and strengthen their emergency response capabilities for National Environmental Awareness Month.

Understanding Lithium-Ion Battery Chemical Hazards: What Recent Incidents Teach Us About Preparedness

This blog explores why battery failure produces dangerous hazardous fumes, how these events escalate into hazardous areas, and why emergency response personnel need fast, water-free neutralization methods to reduce chemical exposure.

When Seconds Matter: Lessons in Chemical Incident Preparedness from the Tennessee Explosion

The U.S. Chemical Safety Board (CSB) has launched an investigation into the October 10, 2025 explosion at Accurate Energetic Systems in McEwen, Tennessee, where 24,000–28,000 pounds of explosive material detonated, killing 16 workers and damaging the industrial chemical facility. Early findings suggest the blast began during heating operations and triggered secondary detonations in nearby storage areas. The incident underscores the ongoing need for robust chemical safety measures, emergency planning, and readiness for large-scale chemical incidents.

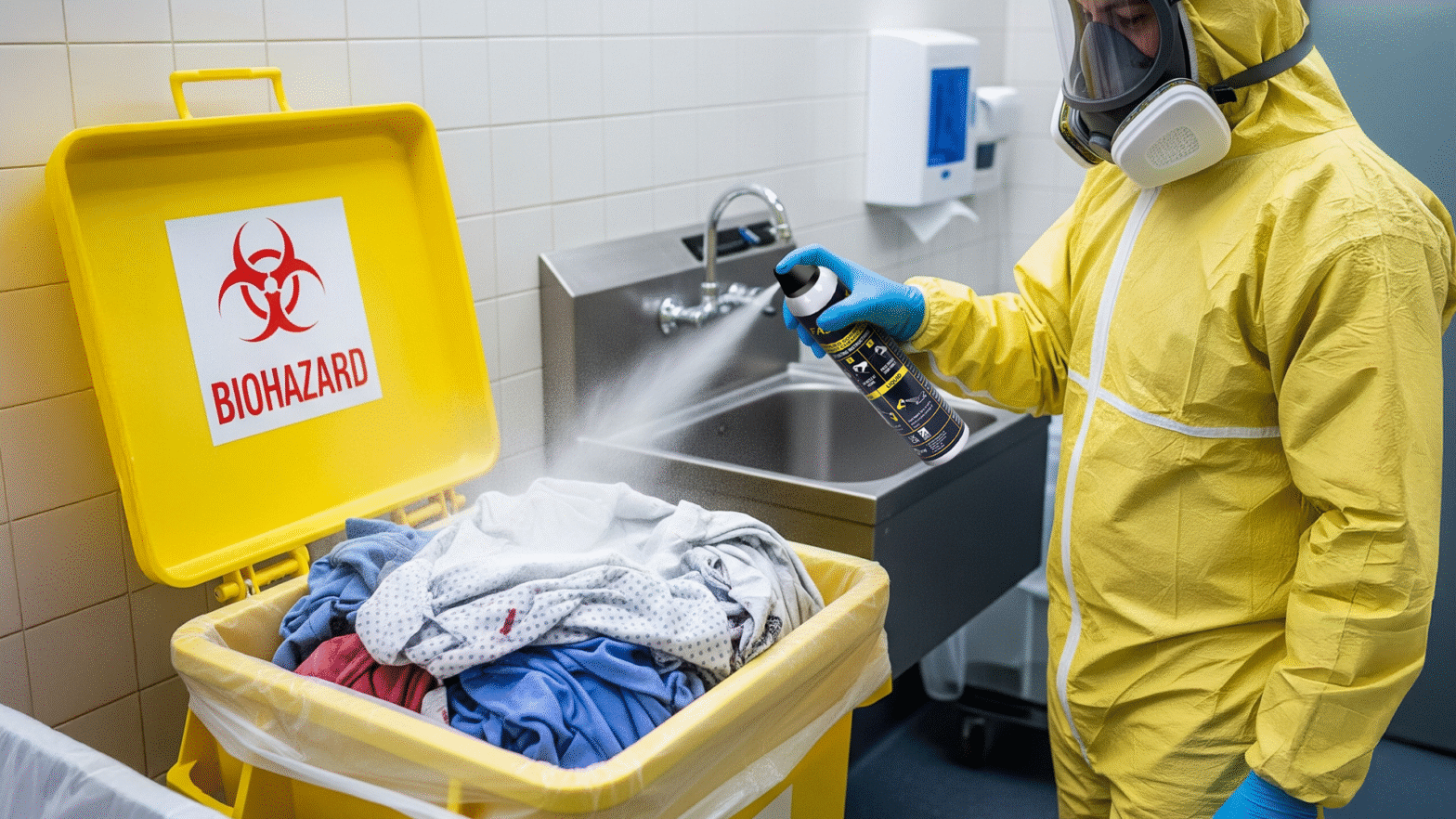

Hospital Dry Decontamination: A Faster, More Efficient Approach to Emergency Response

During a mass casualty incident involving chemical agents or hazardous materials, every second counts. Hospitals must act quickly to protect patients, staff, and infrastructure while maintaining operations within the hospital environment. Traditional wet decontamination systems, which rely on large volumes of water and extended setup, can slow down an emergency response when speed is critical. … Continue reading Hospital Dry Decontamination: A Faster, More Efficient Approach to Emergency Response

Why Effective Chemical Spill Response Matters in Industrial Settings

We’ll look at several industries where chemical spills are a pressing concern—including lithium-ion battery facilities, mining operations, and transportation hubs such as airports and ports—and explore how the right tools and response strategies can protect workers, reduce risks, and keep operations running safely.

FAST-ACT vs. Traditional Sorbents: A Smarter Solution for Industrial Chemical Response

For decades, many sites have relied on traditional absorbent materials like soda ash, vermiculite, or clay absorbents. While these are common in spill kits and spill response kits, they have one fundamental limitation: they do not neutralize hazardous chemicals. Instead, they merely soak up or contain a substance, leaving potential hazards and health risks behind.