Recent military exchanges involving Iran, Israel, and the United States — including missile strikes and retaliatory actions — have increased instability across parts of the Middle East. Public reporting from NBC News and the BBC describes expanding cross-border activity and heightened military alert levels. As tensions rise, defense sectors reinforce preparedness across the full Chemical – Biological – Radiological – Nuclear (CBRN) spectrum to ensure readiness against both conventional and unconventional threats.

Tag: FAST-ACT training

FAST-ACT February Highlights: Advancing Dry Decontamination Readiness Through Training and Global Engagement

February was a strong month for FAST-ACT as our team continued supporting responder preparedness through hands-on demonstrations and international engagement.

What Is Your Unidentified Hazardous Materials Response Strategy?

When a material is unknown, delaying action can increase exposure risk, allow contamination to spread, and endanger both responders and the public. An effective emergency response plan must account for this reality and prioritize immediate hazard reduction alongside identification efforts.

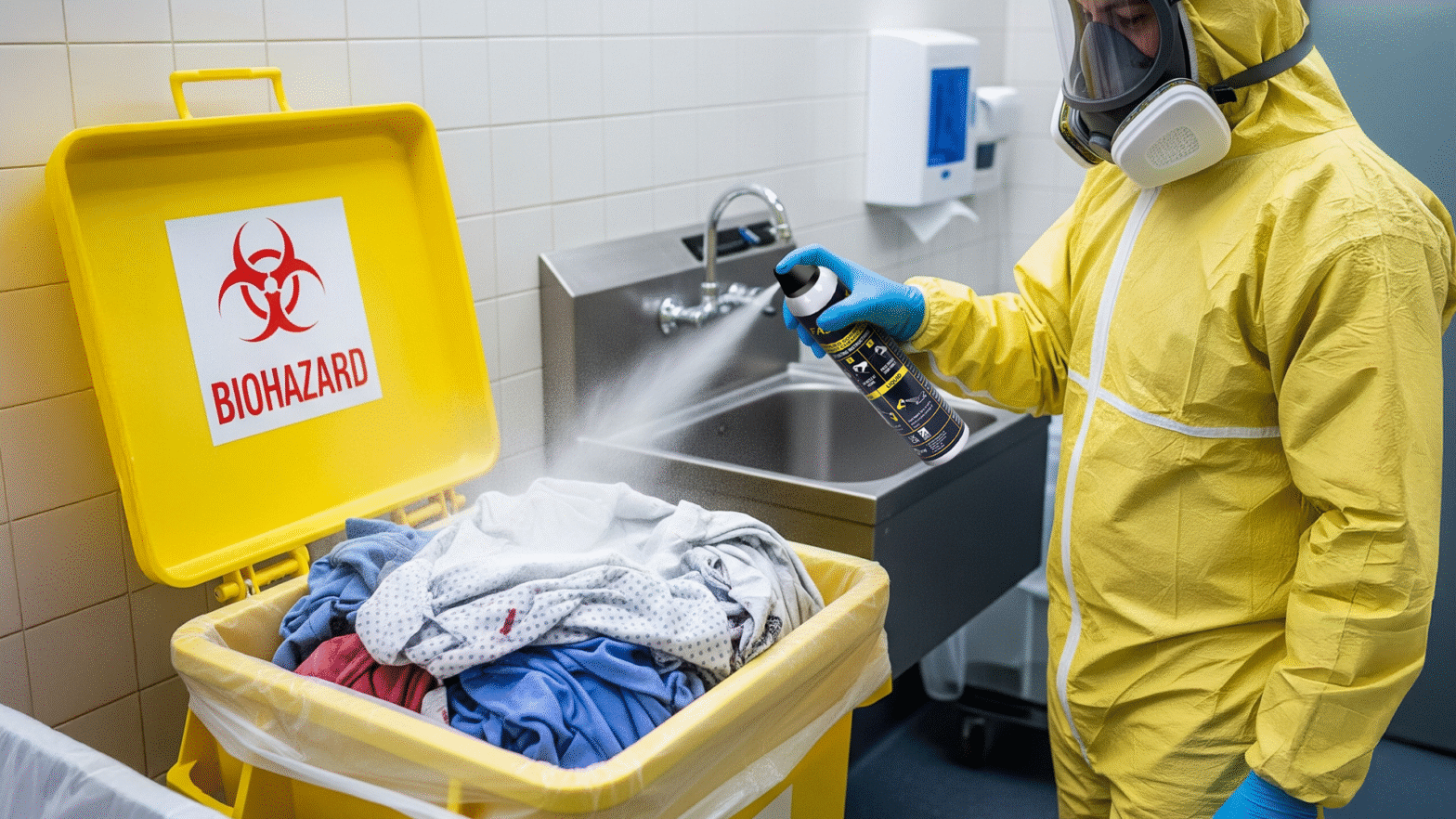

Hospital Chemical Decontamination Readiness: Why Many Facilities Are Still Unprepared

Hospitals today face increasing risks from hazardous materials, chemical incidents, toxic industrial chemicals (TICs), and chemical warfare agents (CWAs). These events require specialized safety protocols, appropriate Personal Protective Equipment (PPE), and established decontamination protocols to protect both staff and patients. Yet most facilities remain underprepared to manage a chemical release or mass chemical exposure during a mass casualty event. A recent report revealed that nearly 70% of hospitals are unprepared for chemical and biological emergencies. Additional research supports this trend: many emergency departments lack operational readiness for chemical emergency medical management or hospital patient decontamination.

National Environmental Awareness Month: Strengthening Environmental Chemical Hazard Response Across Industrial Operations

This blog will cover how key industries—including mining, oil and gas, environmental remediation, and battery manufacturing—manage chemical hazards and strengthen their emergency response capabilities for National Environmental Awareness Month.

FAST-ACT November Event Highlights: Advancing CBRN Readiness Across the Nation

This November, the FAST-ACT team continued its commitment to advancing chemical preparedness and CBRN defense through nationwide engagement and collaboration. From Charleston to Los Angeles and Fort Campbell, FAST-ACT and its partners showcased how dry decontamination technology enhances operational readiness and response efficiency across military, emergency, and defense sectors.

Why Combined Wet and Dry Decontamination Is the New Gold Standard for Hospital Emergency Preparedness

Across Level 1 trauma centers in the U.S., Sweden, Canada, and Singapore, teams now deploy combined decontamination methods—a hybrid model proven to improve outcomes, optimize speed, and reduce risks from hazardous chemicals. This approach aligns with hospital emergency preparedness standards that prioritize rapid, safe, and patient-centered decontamination workflows.

Eyes on the Zone: Securing FIFA 2026 Fan Areas Against Emerging CBRN Threats

This blog will cover how Emergency Response Teams, security sector professionals, and regional governments can integrate dry decontamination technologies and vapor threat neutralization strategies into their event playbooks to ensure safe, efficient, and scalable response to Chemical Warfare Agents, Biological attacks, terror incidents, or lithium-ion battery fires that may arise in high-density environments.

Hospital Dry Decontamination: A Faster, More Efficient Approach to Emergency Response

During a mass casualty incident involving chemical agents or hazardous materials, every second counts. Hospitals must act quickly to protect patients, staff, and infrastructure while maintaining operations within the hospital environment. Traditional wet decontamination systems, which rely on large volumes of water and extended setup, can slow down an emergency response when speed is critical. … Continue reading Hospital Dry Decontamination: A Faster, More Efficient Approach to Emergency Response

The Shift Toward Dry Decontamination: Funding, Adoption, and the Future of CBRN Preparedness

In this blog, we’ll examine why dry decontamination is gaining momentum, highlight Europe’s leadership and funding efforts, and explore how global organizations—including FAST-ACT—are adopting these solutions to strengthen preparedness for CBRN threats. standard.